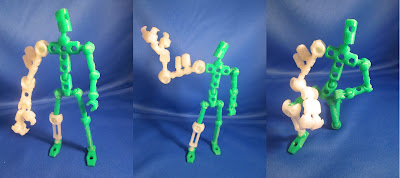

Did a couple of things different this time:

- Scaled everything to 130%. This was to hopefully increase wall thickness and fudge the tolerances. Mostly successful, except how the bot is big.

- Tried standing all ball-on-one-side-socket-on-the-other parts vertically on the ball to further minimize contact with the support material. Failed every time and I tried many variations including adding my own supports. There just wasn't enough holding the part to the platform and they wiggled themselves to spaghetti.

- Anything that had to be 100% supported (no flat surfaces to print from) was elevated 5mm off the build platform. The theory was that when the balls were right on the build surface the support material under them didn't have enough layers to form under them. It was partially successful, but I discovered that while better than when using ABS the balls joints still weren't really round and had to be sanded into shape.

During assembly I only had 3 breaks, the left hip socket and two of the claws. The claws still had enough to hold on well but the hip socket only held on long enough to take some pictures.

Got to print the arm from one of the kickstarter kits. Used my white PLA for that. I call the middle one "lament of the cyborg".

The result was super posable and despite some roughness with PLA against PLA (it doesn't seem to slide like ABS and it definitely doesn't flex), after a little sanding to make the ball joints rounder it all fit almost perfectly. However in the arm accessory kit there was a new kind of joint, one that came around the ball on 2 sides instead of 3 and the result was the best joint of the bunch for hold, pose, and assembly. I would say to Wayne that all sockets need to have a split down the side separating it into two halves so it flexes during assembly. It doesn't need to be fully split like the wrist joint (or what I'm using as a wrist joint anyways) just a 2-3mm slit down the third side to add some flex is all. I would also say that increasing the joints to 130% would help. Not everything needs to be bigger, just the joints, tho the result might be a bit funny looking, I don't know.

I'll be sending a print to Wayne Loosey here soon with supports attached for educational purposes. Maybe we'll see a completely home 3D printer friendly version one day.

I would also say to Makerbot why do I have to edit a text file to adjust filament diameter?! I'm gonna keep harping on this until they fix it. That is the only setting I feel like I need exposed.

In other news I'm very close to finishing Makerbot Project Blueprints, but things have taken a pause on my end while I wait for the proofers to check the last couple of chapters. I accidentally listed url wrong on the associated files making it impossible for them to proceed until I told them what it should have been. But we're past that bump now and hopefully finished with the 2nd draft quickly, then on to the final print layout. Exciting stuff.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.